When Sphere Fluidics needed to interface its microfluidics platform with scientific instrumentation to develop a solution for automated high-throughput mass spectrometry analysis, it turned to National Instruments (NI) measurement hardware and software – and ultimately to Wiresmith Technology’s proven development skills. Dr Xin Li, Group Leader and microfluidics expert at Sphere Fluidics (SF), outlines the challenges his team faced, and explains how Wiresmith and NI helped accelerate their product development cycle, providing the FPGA development expertise needed to realise their idea and successfully deliver a fully functional solution on time.

Sphere Fluidics

Originally spun out from the University of Cambridge, SF is a life sciences company specialising in developing novel technologies for single cell analysis and characterisation. Its patented technologies help scientists screen for and isolate rare and valuable biological variants valuable across research, therapeutic, bioproduction and diagnostic applications. By boosting assay throughput and sensitivity, while reducing costs and saving time, SF aids R&D into new drugs and vaccine generation.

Sphere Fluidics’ proprietary technology enables ultra-high throughput screening, analysis and processing of millions of isolated, individual cells in miniaturised picodroplets (effectively miniature ‘test tubes’ for single cells), SF’s microfluidic platform can make these aqueous picodroplets in oil at a rate of over 100,000 per minute, producing, manipulating, incubating, analysing, sorting, fusing, splitting, retrieving and dispensing millions of picodroplets each day.

Sphere Fluidics’ Idea

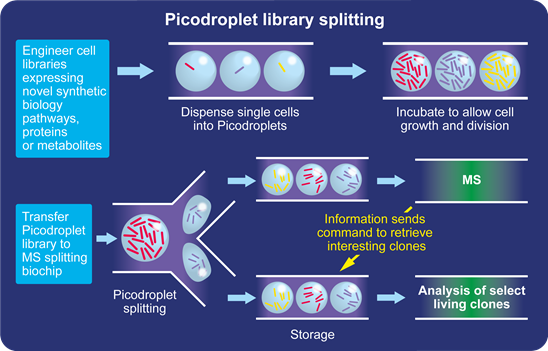

In developing a new workflow for one of its customers, SF faced the challenge of interfacing its microfluidics platform with a PerkinElmer AxIon II mass spectrometer (MS) for analysis of the picodroplets. Since MS analysis is an inherently destructive process, SF’s idea was to develop a system which could enable the retrieval of living copies of ‘hits’ that are normally destroyed during MS procedures. It works by firstly encapsulating individual microbes and then incubating them in growth media to enable metabolism and cell division. The picodroplet library is then transferred to an MS splitting biochip, where one replicate picodroplet is sent for analysis and the other remains stored on the biochip. When a ‘hit’ or clone of interest is identified during MS analysis, the corresponding stored picodroplet can be retrieved and further investigated.

Splitting of the Picodroplets

The first obstacle was to find a way to stream data out of the MS to automate the application, rather than rely on its standard display interface, before using it to track and sort the picodroplets in real time. SF originally planned to use a microprocessor solution to bridge the two parts of the system, automating the measurement, analysis and control of the picodroplets – but the time required to develop such a solution rendered it prohibitive using SF developer resources. Since its microfluidics platform already used National Instruments LabVIEW measurement and control software, SF turned to NI engineers to assess alternative solutions.

Initially, the team attempted to use an NI data acquisition device, but due to loop times being too high, it simply did not have the reaction times to read and sort the stream of picodroplets from the microfluidics platform. FPGA (field-programmable gate arrays) hardware offered the required speed of the microprocessor solution, but with much faster development – as well as greater reconfigurability. And using NI FPGA meant LabVIEW could be used as a common software platform. But lacking the in-house LabVIEW FPGA programming experience, SF looked to NI for help in realising its idea. NI recommended Wiresmith Technology and James McNally.

The Solution

Wiresmith worked with the Sphere Fluidics team to accelerate their product development cycle, providing the FPGA development expertise needed to realise its idea and successfully deliver a fully functional solution on time.

In earlier stages of the project, SF engineers worked directly with the MS manufacturer to develop a C# application to stream data out of the instrument and interface with the SF microfluidics platform over TCP. Wiresmith's LabVIEW expertise allowed it to integrate the MS communications directly, eliminating additional complexity. Taking the algorithm the SF team had developed to screen the picodroplets (before splitting them into two streams for MS analysis or storage and retrieval), Wiresmith were able to implement it in FPGA, integrating it with both the microfluidics platform and the MS. Replacing multiple complex software elements with a single integrated LabVIEW workflow and interface resulted in greatly enhanced usability.

The FPGA triggers a sorting on a positive sample. Look for the picodroplet that goes to the top channel.

The FPGA boards connected to two photo-multiplier-tubes (PMTs) for picodroplet detection, and a high voltage amplifier to drive the electrodes for picodroplet sorting. The FPGA implemented picodroplet detection, classification, counting and synchronisation detection. Once synchronised, it generated the correct pulses for sorting with microsecond timing precision. The system could also log high-speed data from the FPGA for post analysis. The program’s simple operation enabled the scientists to iterate on designs for other parts of the system (including biochip design and picodroplet composition), as well as configure key parameters, such as molecular weight.

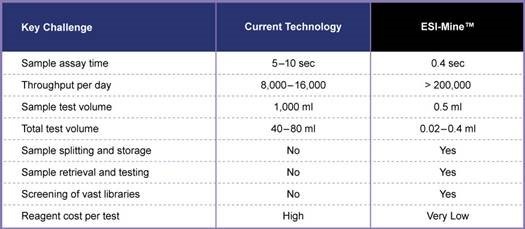

The system developed allows the analysis of samples in less than 10% of the traditional time, combined with the ability to retrieve the samples should accelerate scientists research and development into new treatments for improved healthcare.

ESI Mine Comparison Table

“Without James and Wiresmith Technology, it simply would not have been possible to realise our idea and deliver this project on time and within budget,” explained Dr Xin Li, Group Leader at Sphere Fluidics. “His software development skills allowed the team to focus on their complementary expertise, knowing they could rely on his timely delivery and technical excellence – while regular communication from James kept the project running smoothly. This success helped position Sphere Fluidics as a pioneer and leader in mass spectrometer and microfluidic integration – and has resulted in a number of customer projects in this field. Based on this experience, Wiresmith will be our partner of choice as we develop these future systems.”

Further Reading

About Wiresmith:

Wiresmith Technology is a software development consultancy that specialises in developing automated data acquisition systems to help engineers realise their ideas. Founded by James McNally in 2014, after working as a software engineer for NI, Wiresmith has successfully delivered projects across diverse engineering fields including mechanical engineering, automotive, energy and scientific instrumentation. As a National Instruments Alliance Partner, Wiresmith is recognised and certified by NI for its expert knowledge of NI software and hardware technologies – and its ability to deliver projects based on them. With more than a decade of experience, McNally is an industry-recognised expert in applying NI technologies to automated measurement and control problems. He is a Certified LabVIEW Architect, Certified LabVIEW Embedded Developer and a LabVIEW Champion.